Siemens AG - Regensburg

An energy audit was carried out for the Siemens production site in Regensburg. Various measures were developed to improve efficiency, save electricity and natural gas and reduce CO2 emissions. The measures range from simple improvements that can be implemented quickly to more elaborate investment measures with high cost savings.

Key data on the project

Siemens AG - Elektroinstallationswerk Regensburg

High-quality protection components for electrical installations are produced in Regensburg. The focus is on residual current circuit breakers, miniature circuit breakers and the fire protection switch as an innovative product.

Industry sector

Electrical engineering

Project location

Regensburg

Target group

Large industrial enterprises

Keywords

Energy audit, efficiency measures

Customer benefits

Fulfilment of the legal obligation to conduct an energy audit and reduction of energy consumption through the energy efficiency improvement measures identified.

Task

In accordance with the current legal situation (Energy Services Act EDL-G 2015), Siemens and its subsidiaries were also obliged to conduct an energy audit.

eta Energieberatung carried out all the steps necessary for legally compliant fulfilment of the legal requirement.

Results

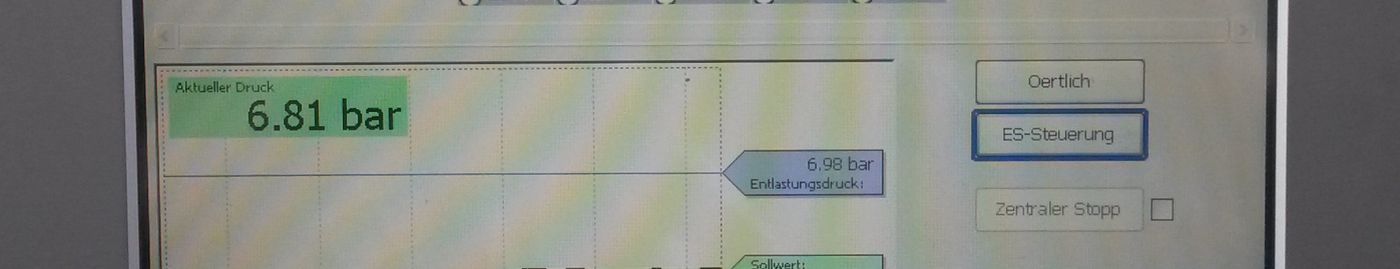

Based on the analysis of the current situation, measures were developed to reduce energy consumption and increase energy efficiency. The savings were quantified and the costs expected for implementation were determined. An economic efficiency calculation was carried out for each measure.

We help you with energy audits

We would be pleased to support you in the introduction of an energy management system according to DIN EN ISO 50001 or comparable systems as well as in the implementation of energy audits.

We will also find the tailor-made solution for you and create a concept which we will then implement together with you.

Call me without obligation or write me an e-mail.

Bernhard Negele